A New Type of Finned Tube: Titanium-Copper and Titanium-Aluminum Composite Finned Tubes

In the world of heat exchangers, the quest for efficiency is never-ending. Traditional finned tubes have served us well for many years, but the time has come for a new generation of heat exchangers that can push the boundaries of performance.

These innovative finned tubes are made from a combination of two metals, each with its own unique properties. Titanium is known for its exceptional strength and corrosion resistance, while copper and aluminum are excellent conductors of heat. By combining these metals, we have created finned tubes that offer a number of advantages over traditional designs.

In the quest for superior heat exchange efficiency and durability, GAOFA TECH has developed two groundbreaking products: Titanium-Copper Composite Finned Tubes and Titanium-Aluminum Composite Finned Tubes. These advanced finned tubes combine the exceptional properties of titanium with the excellent thermal conductivity of copper and aluminum, offering unparalleled performance in various industrial applications.

Contact us: chen@gaofatech.com

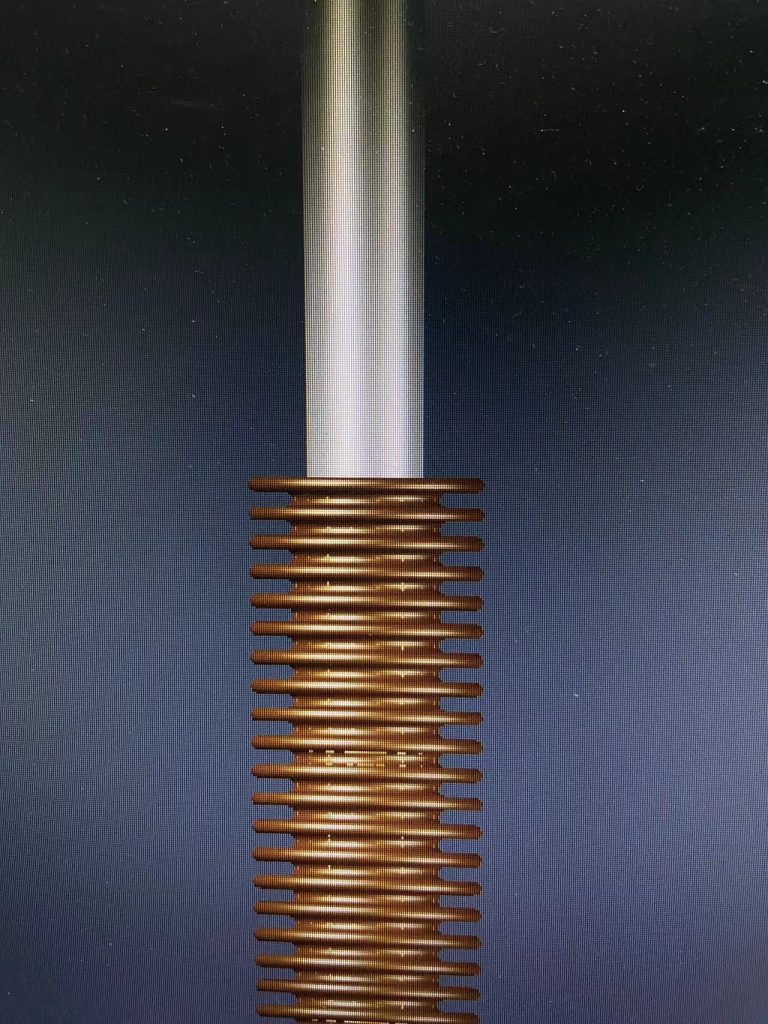

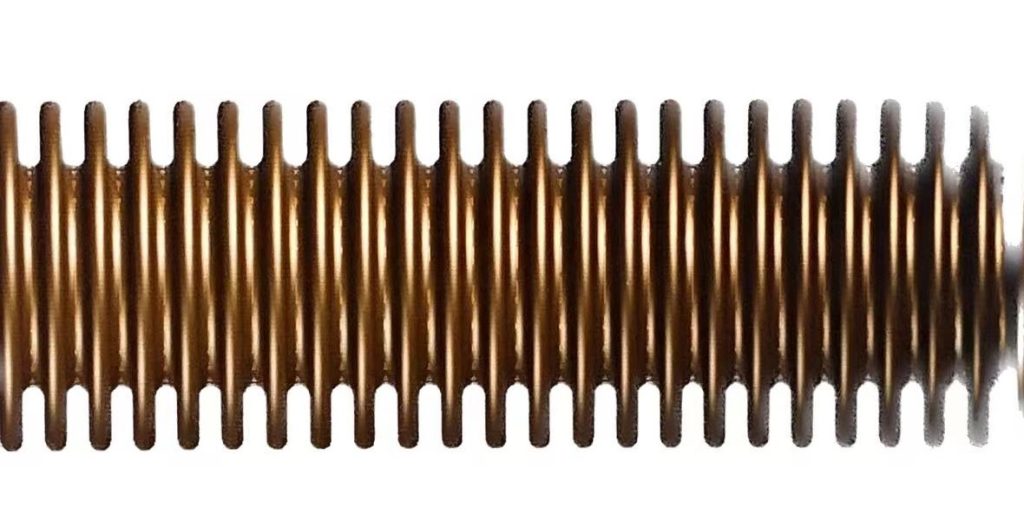

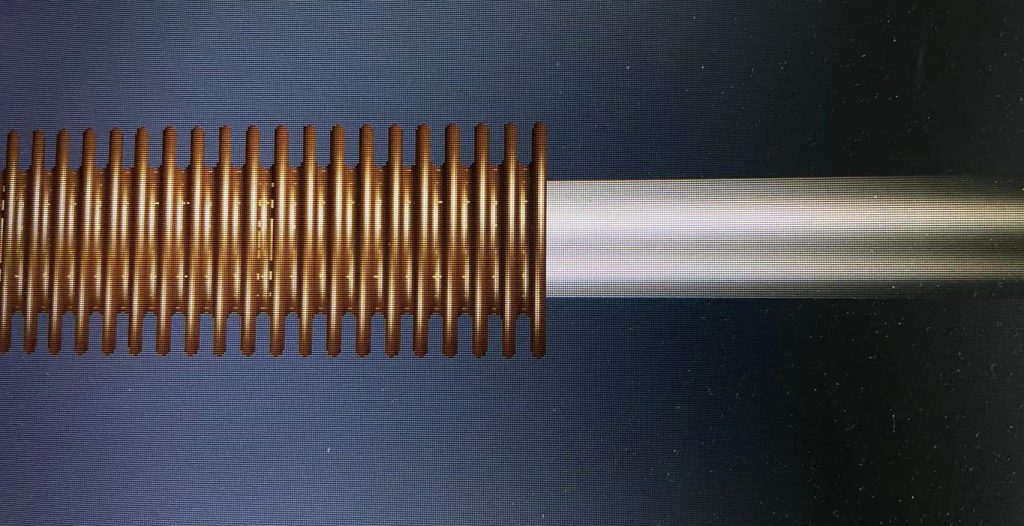

Titanium-Copper Composite Finned Tubes: Boosting Heat Transfer by 500%

Titanium-Copper Composite Finned Tubes represent a significant advancement in heat exchanger technology. The base tube is made of titanium, renowned for its outstanding corrosion resistance, making it ideal for applications in harsh environments such as marine and chemical processing industries. The copper fins, with their superior thermal conductivity, dramatically enhance the heat transfer capabilities of the tubes.

Key Features:

Enhanced Heat Transfer Efficiency: The integration of copper fins with a titanium base tube results in a heat transfer efficiency that is five times higher than that of traditional finned tubes. This substantial increase in efficiency leads to improved performance in heat exchange applications.

Exceptional Durability: Titanium’s inherent resistance to corrosion and high temperatures ensures a longer lifespan, reducing maintenance costs and downtime.

Cost-Effective Solution: By leveraging the strengths of both titanium and copper, these composite finned tubes offer a high-performance, cost-effective alternative to all-titanium or all-copper solutions.

Contact us: chen@gaofatech.com

Titanium-Aluminum Composite Finned Tubes: Achieving 300% Higher Heat Transfer Efficiency

Titanium-Aluminum Composite Finned Tubes offer a perfect balance of efficiency, durability, and cost-effectiveness. The titanium base tube provides robust protection against corrosion and mechanical stress, while the aluminum fins, known for their lightweight and high thermal conductivity, significantly boost the heat transfer efficiency.

Key Features:

Improved Heat Transfer Efficiency: The use of aluminum fins enhances the heat transfer efficiency by three times compared to conventional finned tubes, making these tubes highly effective in various applications.

Lightweight and Strong: The lightweight nature of aluminum reduces the overall weight of the tube assembly without compromising structural integrity, making these tubes ideal for applications where weight is a critical factor.

Economic Advantage: These composite tubes offer a high-performance solution at a competitive price, making them a preferred choice for many industries.

Contact us: chen@gaofatech.com

Applications of Titanium-Copper and Titanium-Aluminum Composite Finned Tubes

These new composite finned tubes have a wide range of potential applications, including:

Power generation: Titanium-copper and titanium-aluminum composite finned tubes can be used in power plant condensers and heat exchangers to improve efficiency and reduce cooling water consumption.

HVAC systems: These tubes can be used in air conditioning and refrigeration systems to increase heat transfer and reduce energy consumption.

Chemical processing: Titanium-copper and titanium-aluminum composite finned tubes can be used in chemical reactors and heat exchangers to handle corrosive fluids and improve reaction efficiency.

Oil and gas: These tubes can be used in oil and gas production and refining processes to improve heat transfer and reduce energy consumption.

Contact us: chen@gaofatech.com

The introduction of Titanium-Copper Composite Finned Tubes and Titanium-Aluminum Composite Finned Tubes by GAOFA TECH marks a significant milestone in the field of heat exchange technology. These advanced tubes not only offer superior heat transfer efficiency—five times greater for the copper variant and three times for the aluminum variant—but also provide exceptional durability and cost-effectiveness.