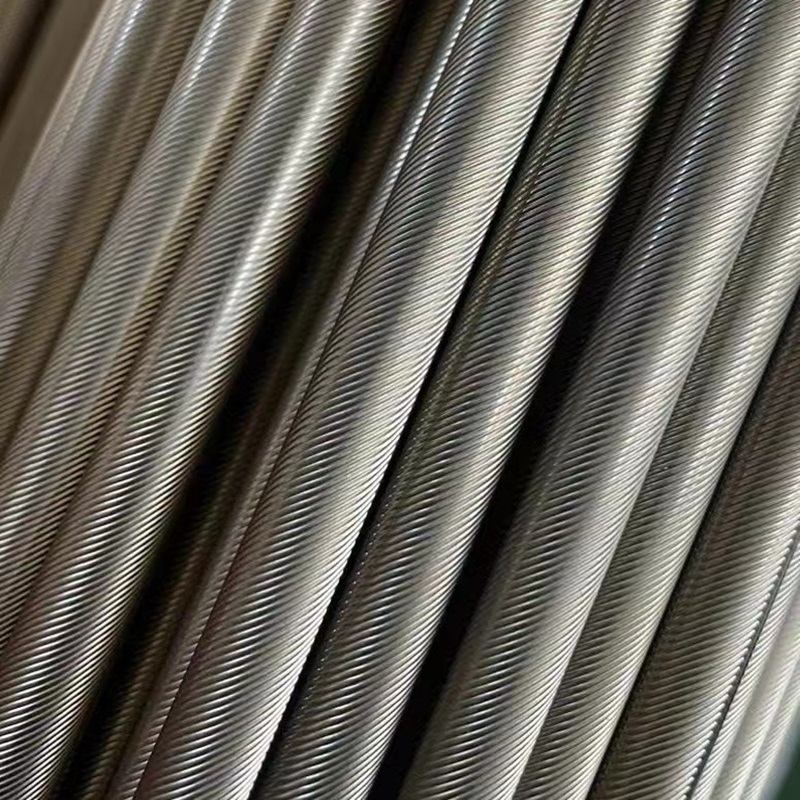

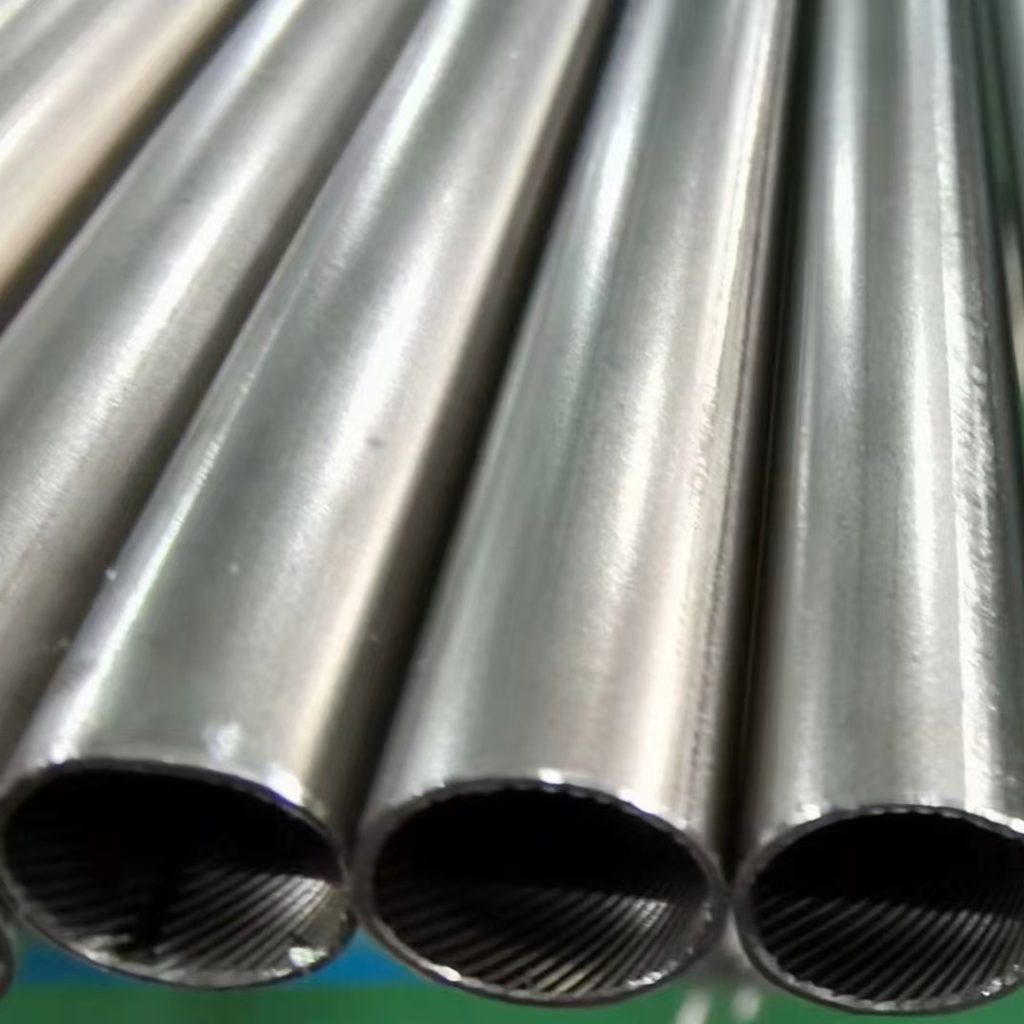

TITANIUM INNER GROOVED TUBE

FROM RAW MATERIAL TO FINISHED TUBE PRODUCTS

High-Performance Titanium Inner Grooved Tubes for Enhanced Heat Transfer and Corrosion Resistance

Titanium inner grooved tubes are specialized tubular products designed with internal helical or spiral grooves along their inner surface. These grooves enhance heat transfer efficiency by increasing the surface area and promoting better fluid turbulence. Made from high-grade titanium, these tubes offer excellent corrosion resistance, making them ideal for use in harsh environments such as chemical processing, marine applications, and HVAC systems. Their lightweight and strong mechanical properties also contribute to improved system performance in heat exchangers and condensers, particularly in industries where weight and durability are critical.

Titanium Inner Grooved Tube:

Material: Titanium, Stainless Steel

Request a QuoteStainless: 304, 304L, 316L, etc.

Titanium: Gr1, Gr2

Tube OD: 7mm, 7.94mm, 9.52mm, 12.7mm

Bottom Wall Thickness: 0.3mm, 0.4mm, 0.5mm

Groove depth: 0.1mm, 0.12mm, 0.13mm, 0.14mm, 0.15mm, 0.2mm max depended on the tube wall thickness.

Tube OD: 7mm, 7.94mm, 9.52mm, 12.7mm

Bottom Wall Thickness: 0.3mm, 0.4mm, 0.5mm

Groove depth: 0.1mm, 0.12mm, 0.13mm, 0.14mm, 0.15mm, 0.2mm max depended on the tube wall thickness.

Introduction

Titanium Inner Grooved Tube and Stainless Steel Inner Grooved Tube

Titanium inner grooved tubes are known for their exceptional corrosion resistance, lightweight nature, and high strength. These tubes are designed with internal grooves that significantly improve heat transfer by increasing surface area and inducing better fluid turbulence. Titanium’s natural resistance to seawater, chemicals, and high temperatures makes it a top choice for demanding applications in industries such as marine, chemical processing, and advanced heat exchanger systems. Additionally, its lightweight properties contribute to better energy efficiency and reduced system weight, particularly important in industries where these factors are critical.

Stainless steel inner grooved tubes, while heavier than titanium, are widely used for their durability, good corrosion resistance, and cost-effectiveness. Stainless steel is suitable for less extreme environments, such as HVAC systems, automotive applications, and refrigeration units, where it provides a reliable and economical solution. The internal grooves also enhance heat transfer efficiency, making stainless steel tubes a practical choice for a broad range of heat exchange applications.

Both titanium and stainless steel inner grooved tubes offer enhanced heat transfer performance, titanium is preferred for more aggressive, corrosive environments due to its superior properties, whereas stainless steel is favored in situations where cost-efficiency and mechanical strength are more important.

Besides inner grooved tubes, GAOFA Tech also supply other high High Efficiency Tubes