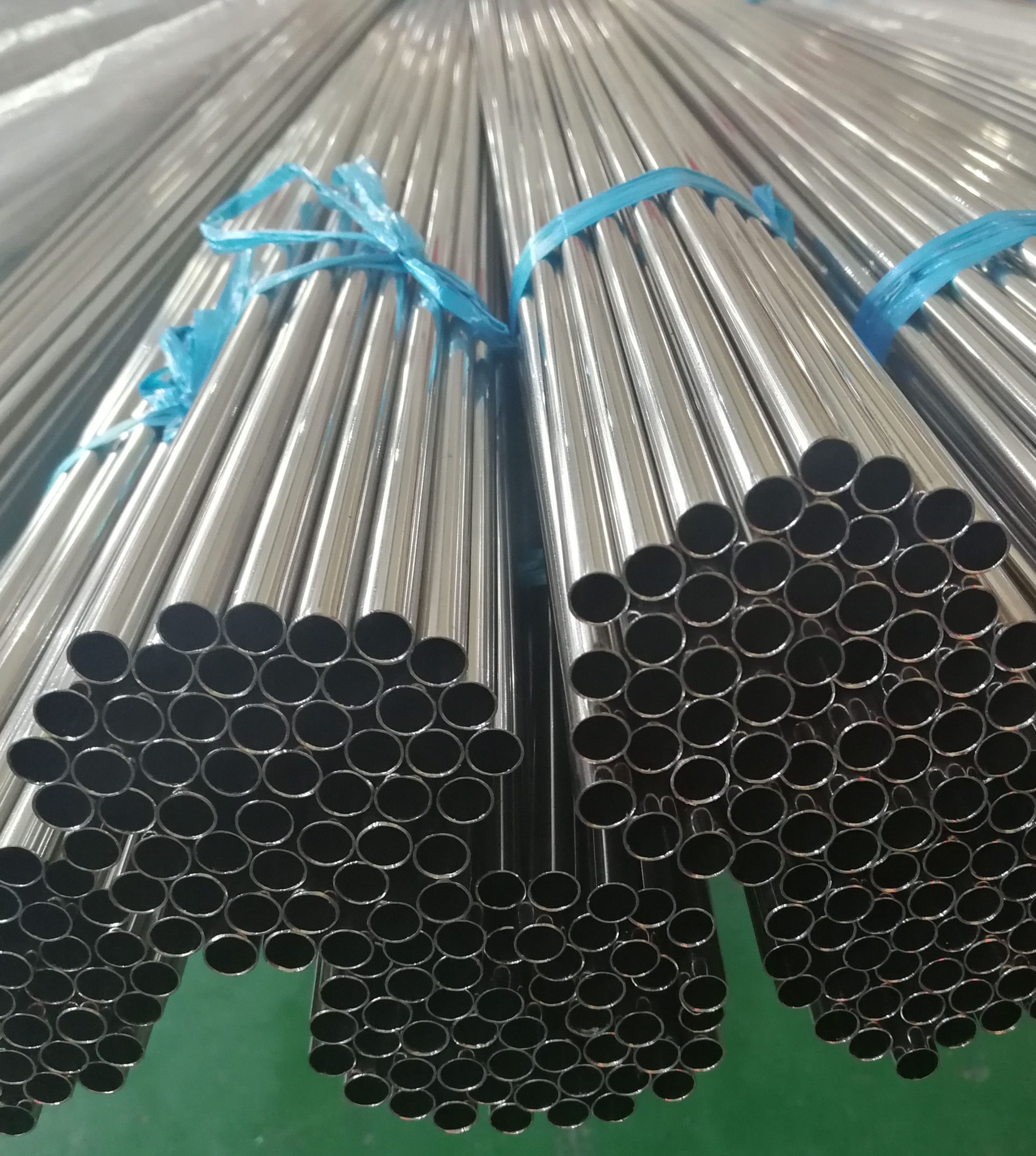

HASTELLOY C276 TUBE

Leading Manufacturer of HASTELLOY C276 TUBE

Upgrade Your Equipments with High-Quality HASTELLOY C276 Tubes. Discover Superior Solutions at GAOFA TECH.

Achieve unparalleled success for your online business with GAOFA TECH! We offer superior HASTELLOY C276 tubes that redefine excellence. Trust our premium solutions to optimize your heating elements and unlock your business's true potential.

HASTELLOY C276 Tube Specification:

ASTM B622, ASTM B626

Welded Pipes & Tubes:

Outer Diameter: 6.0mm to 88.9mm

Wall thickness: 0.3mm to 2.0mm

Seamless Pipes & Tubes:

Outer Diameter: 2.0mm to 114mm

Wall thickness: 0.3mm to 8.0mm

Length: Standard 6000mm, but we can adjust based on customer’s requirement.

Heat Treatment: Inline bright annealing

NDT: Hydrostatic, Pneumatic, E.T. U.T based on standard or customers’ requirements.

Introduction

HASTELLOY C276 is a nickel-chromium-molybdenum wrought alloy considered to be the most widely used corrosion-resistant alloy today. This alloy resists the formation of grain boundary precipitates in the heat-affected zone of the weld, thus making it suitable for most chemical process applications (under welding conditions). C-276 alloy also has excellent resistance to pitting, stress corrosion cracking, and oxidation up to 1900°F. C-276 alloy has excellent resistance to a variety of chemical environments.

Some typical applications for HASTELLOY C276 include components of equipment in chemical and petrochemical organic chloride processes and processes utilizing halide or acid catalysts. Other industrial applications include pulp and paper (digester and bleach areas), scrubbers and piping for flue gas desulfurization, pharmaceutical and food processing equipment.

HASTELLOY C-276 is a nickel-chromium-molybdenum alloy with universal corrosion resistance unmatched by any other alloy. It has excellent resistance to a variety of chemical processing environments, including ferric and copper chlorides, thermally polluted inorganic acids, solvents, chlorine and chlorine-contaminated organic and inorganic pollutants, dry chlorine gas, formic and acetic acids, ethane Anhydrides, seawater and saline solutions, hypochlorite and chlorine dioxide solutions. C276 alloy also prevents the formation of grain boundary precipitates in the weld heat-affected zone, making it usable for most chemical processes in the welded state. It has excellent resistance to pitting and stress corrosion cracking.

HASTELLOY C276 sheet, heat treated at 2050°F, 0.044" thick, rapidly quenched to an average depth of 0.48". C-276 alloy can be successfully fabricated by a number of methods. Alloys tend to harden, but with proper care, alloys are easily hot and cold formed.

Features of HASTELLOY C276:

1. HASTELLOY C276 is one of the few alloys that can resist wet chlorine, hypochlorite and chlorine dioxide solutions.

2. HASTELLOY C276 has excellent resistance to strong oxidizing solutions such as ferric chloride and copper chloride.

3. HASTELLOY C276 is not prone to grain boundary precipitation under welding conditions, so it is suitable for many chemical process applications.

Application of HASTELLOY C276:

1. Digesters and bleach plants in the paper industry.

Request a Quote2. Components exposed to acid gas.

3. Flue gas desulfurization equipment.

4. Evaporators, heat exchangers, filters and mixers used in sulfuric acid environments.

5. Sulfuric acid reactor.

6. Organic chloride treatment equipment.

7. Process equipment utilizing halide or acid catalysts.

HASTELLOY C276 Tube Chemical Composition (%):

| Grade | C | Si | Mn | P | S | Cr | Mo | Fe | W | Co | V | Ni |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| HASTELLOY C276 | ≦0.01 | ≦0.08 | ≦1.00 | ≦0.04 | ≦0.03 | 14.50-16.50 | 15.00-17.00 | 4.00-7.00 | 3.00-4.50 | ≦2.50 | ≦0.35 | Bal |

HASTELLOY C276 Tube Mechanical Properties

| Grade | TENSILE STRENGTH MPa | YIELD STRENGTH Rp0.2, MPa | ELONGATION A50mm, % |

|---|---|---|---|

| HASTELLOY C276 | ≧690 | ≧283 | ≧40 |

Standards:

Tubes & Pipes: ASTM B622, ASTM B626

HASTELLOY C276: Density:

0.321 lb/in3 (8.87g/cm3)

Request a Quote