Introduction:

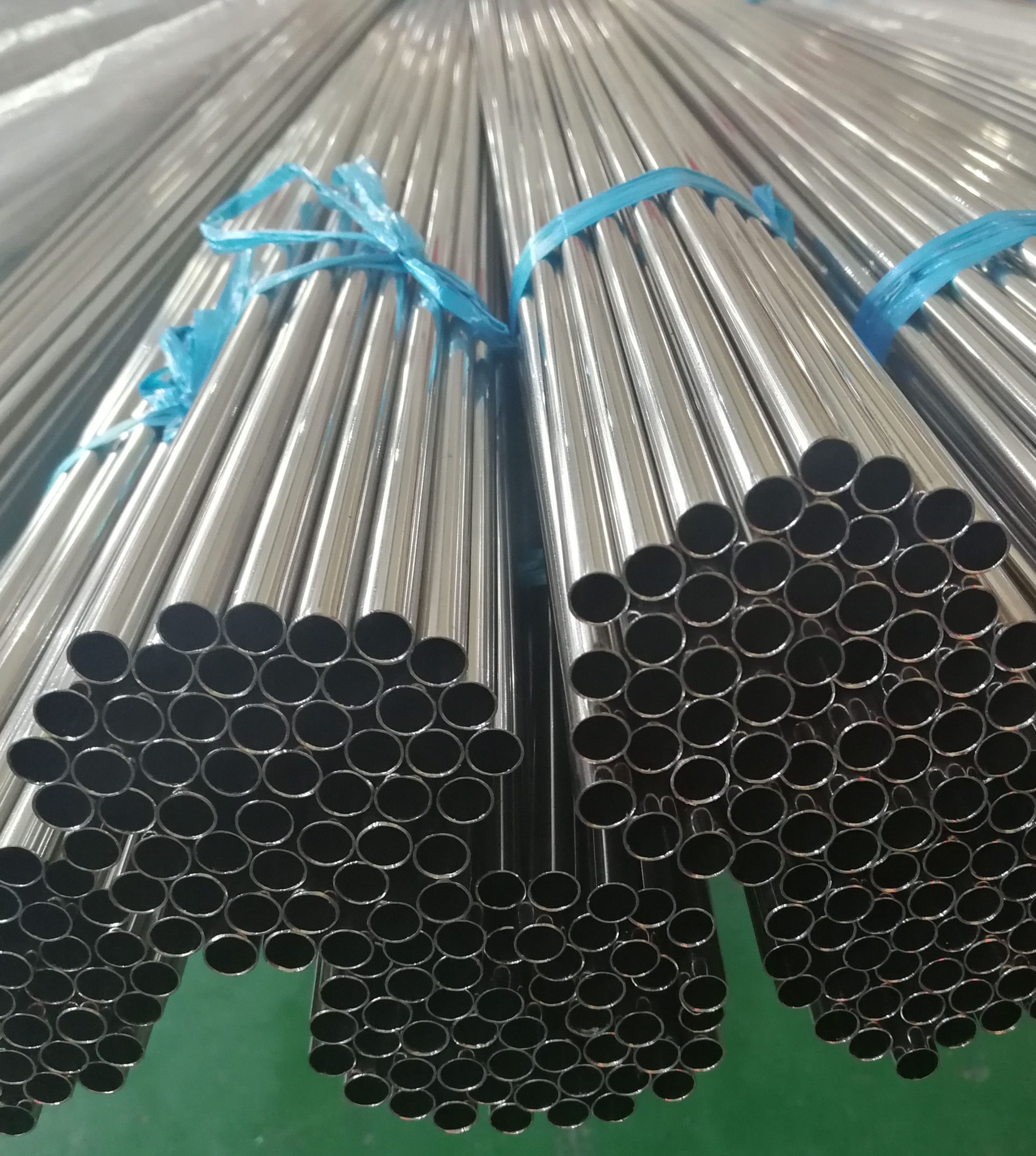

Hastelloy C276, a high-performance nickel-molybdenum-chromium alloy, stands as a cornerstone in the realm of steel tubes. Its exceptional corrosion resistance, versatility in various environments, and mechanical strength make it a preferred choice in critical industrial applications. This article delves into the intricate details of Hastelloy C276 tubes, exploring their properties, environmental adaptability, and wide-ranging applications within the steel pipe industry.

Click here to know more about Gaofa Tech’s Hastelloy C276 tubes.

Key Features:

- Corrosion Resistance:

Hastelloy C276 tubes exhibit outstanding corrosion resistance in aggressive environments, including oxidizing and reducing conditions. Their resistance to pitting, crevice corrosion, and stress corrosion cracking makes them ideal for chemical processing, wastewater treatment, and desalination plants. - High-Temperature Performance:

With a high nickel content, Hastelloy C276 tubes maintain their structural integrity and mechanical properties at elevated temperatures, making them suitable for applications in high-temperature furnaces, incinerators, and exhaust systems. - Versatility in Chemical Environments:

These tubes withstand a wide range of chemicals, including sulfuric acid, hydrochloric acid, acetic acid, and seawater, making them indispensable in industries dealing with aggressive chemical substances. - Mechanical Strength and Durability:

Hastelloy C276 tubes possess excellent mechanical strength, allowing them to endure high-pressure environments and mechanical stress. Their durability ensures reliable performance in critical applications.

Environmental Adaptability:

Hastelloy C276 tubes find extensive use in environments where other materials might corrode or degrade rapidly. Their adaptability to harsh chemical, high-temperature, and corrosive settings makes them essential in industries such as chemical processing, petrochemical, aerospace, and power generation.

Diverse Applications:

- Chemical Processing Industry:

Hastelloy C276 tubes are integral in handling aggressive chemicals, acids, and caustic solutions. They find applications in reactors, heat exchangers, and pipelines within chemical plants. - Oil and Gas Sector:

In the oil and gas industry, these tubes are used in pipelines and downhole applications, where resistance to sour gas, brine, and corrosive drilling fluids is paramount. - Desalination Plants:

Hastelloy C276 tubes play a crucial role in desalination plants, resisting the corrosive effects of seawater and chemicals, ensuring efficient and durable heat exchangers. - Aerospace and Aviation:

These tubes are utilized in aerospace components, offering reliable performance in exhaust systems and engines operating at high temperatures. - Power Generation:

Hastelloy C276 tubes are used in power plants for applications like boiler tubes and steam generators, where resistance to high-temperature and corrosive environments is essential.

Conclusion:

Hastelloy C276 tubes, with their unparalleled corrosion resistance, high-temperature stability, mechanical strength, and versatility in various applications, are integral components within the steel pipe industry. Their ability to thrive in harsh and demanding environments positions them as a cornerstone in modern engineering, ensuring reliability, safety, and progress across diverse industrial sectors.

Note: For specific inquiries or to explore how Hastelloy C276 tube can be tailored to your industry equipment’s needs, please feel free to contact our experts. We are dedicated to provide customized solutions that meet the unique requirements of your industry.