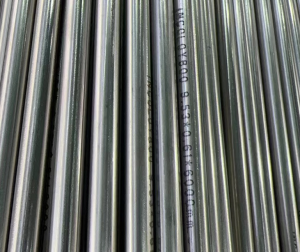

Incoloy 800 tube stands out as a remarkable alloy tubing solution due to its exceptional corrosion resistance and high-temperature capabilities. This special alloy tubing plays a pivotal role in various industries, particularly in the realm of heating elements.

Click here to know more about GAOFA Tech’s Incoloy 800 Tubes.

The Power of Incoloy 800 Tube in Heating Elements:

Features:

1, superior corrosion resistance and wide applications in various conditions.

2, Can be used free from troubles if high corrosion resistance is required, RECOMMENDED MATERIAL.

3. Can be acid-washed or electrolytic-polished as surface processing when used for in-water heating only.

Proper environment: Heating in water, Air heating.

Limit service temperature(UL): 880°C or less.

Application examples:

Fish roasters, microwave oven ranges, small calorifiers, dishwashers, drum washing machines, cup vending machines and heat accumulating heaters and etc.

1. Exceptional Corrosion Resistance:

Incoloy 800 tube is renowned for its robust resistance against corrosion, making it an ideal choice for applications where exposure to harsh chemicals or corrosive environments is a concern. This inherent resistance ensures the longevity and reliability of heating elements, even in challenging industrial settings.

2. High-Temperature Performance:

Heating elements operate under extreme temperatures, demanding materials that can withstand such conditions without compromising performance. Incoloy 800 tube excels in high-temperature environments, maintaining its mechanical properties and structural integrity even at elevated temperatures. This characteristic is crucial for ensuring consistent and efficient heat generation in various heating applications.

3. Versatility and Adaptability:

Incoloy 800 tube offers a high degree of versatility, allowing it to be tailored to specific heating element designs. Its malleability and formability enable manufacturers to create intricate shapes and sizes, catering to diverse heating requirements across industries. Whether used in industrial furnaces, electric heaters, or household appliances, Incoloy 800 tube adapts seamlessly to different heating element configurations.

4. Longevity and Cost-Efficiency:

Investing in heating elements constructed with Incoloy 800 tube translates into long-term reliability and cost-efficiency. The exceptional durability of this alloy tubing minimizes the need for frequent replacements, reducing maintenance costs and downtime. Its longevity ensures consistent performance, making it a cost-effective choice for businesses relying on efficient heating systems.

5. Safety and Reliability:

In applications where safety is paramount, such as in industrial processes or heating systems for critical environments, the reliability of heating elements is non-negotiable. Incoloy 800 tube’s proven track record for safety and reliability makes it a trusted option for engineers and manufacturers aiming to deliver heating solutions that meet stringent industry standards.

In conclusion, Incoloy 800 tube stands as a beacon of reliability, offering unparalleled corrosion resistance, high-temperature performance, versatility, longevity, and safety. Its exceptional properties make it the material of choice for heating elements, ensuring consistent and efficient heat generation across a wide range of applications.

Note: For specific inquiries or to explore how Incoloy 800 tube can be tailored to your heating element needs, please feel free to contact our experts. We are dedicated to provide customized solutions that meet the unique requirements of your industry.