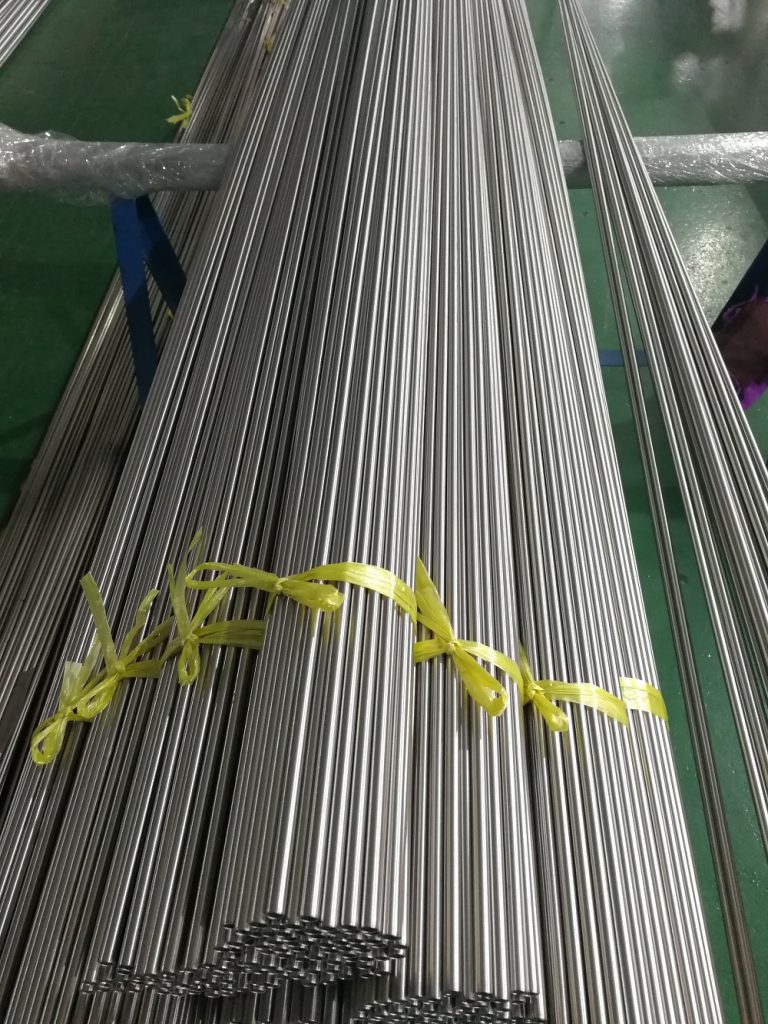

INCOLOY 825 TUBE

Leading Manufacturer of welded Incoloy 825 tube for making heating elements

Enhance Your Heating Elements with Premium Incoloy 825 Tubes. Explore Unparalleled Quality Solutions at GAOFA TECH.

Elevate your business to new heights with GAOFA TECH! As industry leaders, we specialize in delivering top-of-the-line Incoloy 825 tubes that redefine excellence. Our unrivaled commitment to quality ensures that our tubes are perfectly suited for your heating elements products. Trust in our premium solutions tailored to your specific needs, and unlock the true potential of your business.

Incoloy 825 Tube Specification:

ASTM B704, ASTM B423

Welded Pipes & Tubes:

Outer Diameter: 6.0mm to 88.9mm

Wall thickness: 0.3mm to 2.0mm

Seamless Pipes & Tubes:

Outer Diameter: 2.0mm to 114mm

Wall thickness: 0.3mm to 8.0mm

Length: Standard 6000mm, but we can adjust based on customer’s requirement.

Heat Treatment: Inline bright annealing.

NDT: Hydrostatic, Pneumatic, E.T. U.T based on standard or customers’ requirements.

Introduction

Incoloy 825 (Alloy 825, 2.4858, UNS N08825) nickel-based alloy tube and tubing

Incoloy 825 is an nickel-iron-chromium based superalloy with molybdenum, copper and titanium. The chemical composition of this nickel alloy is designed to provide superior resistance to many corrosive environments. It is similar with Incoloy 800, but offering better resistance to water corrosion. It also offers excellent resistance to reducing and oxidizing acids, stress corrosion cracking, and localized corrosion such as pitting and crevice corrosion. Incoloy 825 is particularly resistant to sulfuric and phosphoric acid. This nickel alloy is widely used in chemical process equipment, pickling tank heaters, pickling tanks and equipment, pollution-control equipment, oil and gas well piping, phosphoric acid evaporators etc.

Incoloy 825 is an nickel-iron-chromium based superalloy with molybdenum, copper and titanium. The chemical composition of this nickel alloy is designed to provide superior resistance to many corrosive environments. It is similar with Incoloy 800, but offering better resistance to water corrosion. It also offers excellent resistance to reducing and oxidizing acids, stress corrosion cracking, and localized corrosion such as pitting and crevice corrosion. Incoloy 825 is particularly resistant to sulfuric and phosphoric acid. This nickel alloy is widely used in chemical process equipment, pickling tank heaters, pickling tanks and equipment, pollution-control equipment, oil and gas well piping, phosphoric acid evaporators etc.

Details of contents : Ni:38%-46%, Cr:19.5% - 23.5%, Mo: 2.5% - 3.5%, Cu: 1.5% - 3.0%, Al: 0.2% Max, Ti: 0.6% - 1.2%, Mn: 1.0%Max Fe: Bal.

Incoloy 825 tube heating elements features:

It has excellent corrosion resistance and has a wide range of applications in a variety of conditions.

It can be used free from troubles if high corrosion resistance is required, especially ACID condition, Incoloy 825 is recommended.

Limit service temperature(UL) : 880°C or less

Incoloy 825 tube heating elements application:

Used as heating elements for fish roasters, microwave oven ranges, small calorifiers, dishwashers, drum washing machines, heat accumulating heaters, etc.

Request a QuoteIncoloy 825 Tube Chemical Composition (%):

| Grade | C | Si | Mn | P | S | Ni | Cr | Cu | Al | Ti | Mo | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Incoloy 800 | ≦0.10 | ≦1.00 | ≦1.50 | ≦0.030 | ≦0.015 | 30.00-35.00 | 19.00-23.00 | ≦0.75 | 0.15-0.60 | 0.15-0.60 | --- | BAL |

| Incoloy 840 | ≦0.08 | ≦1.00 | ≦1.00 | ≦0.030 | ≦0.015 | 19.00-22.00 | 18.00-22.00 | --- | 0.15-0.60 | 0.15-0.60 | --- | BAL |

| Incoloy 825 | ≦0.05 | ≦0.50 | ≦1.00 | --- | ≦0.030 | 38.00-46.00 | 19.50-23.50 | 1.50-3.00 | ≦0.20 | 0.60-1.20 | 2.50-3.50 | BAL |

Incoloy 825 Tube Mechanical Properties

| Grade | TENSILE STRENGTH MPa | YIELD STRENGTH Rp0.2, MPa | ELONGATION A50mm, % |

|---|---|---|---|

| Incoloy 800 | ≧520 | ≧205 | ≧30 |

| Incoloy 840 | ≧517 | ≧207 | ≧30 |

| Incoloy 825 | ≧586 | ≧240 | ≧30 |

Standards:

Plate, sheet, strip: ASTM B424

Tube & tubing: ASTM B704, ASTM B751

Incoloy 825 Density:

0.294 lb/in3 (8.14g/cm3)

Request a Quote