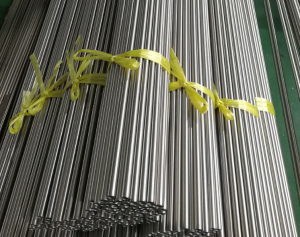

Incoloy 825, a nickel-iron-chromium alloy, emerges as a stellar material in industrial applications owing to its exceptional corrosion resistance and high-temperature strength. Its application in Heating Elements Tubes stands out prominently, especially when compared to its counterpart, Incoloy 800, due to several distinct advantages.

Clicke here to know our Incoloy 825 tubes.

1. Superior Corrosion Resistance:

Incoloy 825 surpasses Incoloy 800 in terms of corrosion resistance. While both alloys offer good corrosion resistance, Incoloy 825 demonstrates exceptional performance in aggressive chemical environments. This characteristic makes it the preferred choice for Heating Elements Tubes, ensuring longevity and reliability even in harsh conditions.

2. Enhanced High-Temperature Durability:

Both alloys exhibit high-temperature strength, but Incoloy 825 retains its mechanical properties at elevated temperatures more effectively than Incoloy 800. This enhanced high-temperature durability ensures consistent and reliable performance in heating applications, making it an ideal choice for industries requiring sustained heat generation.

3. Optimal Performance in Aggressive Environments:

Incoloy 825 outperforms Incoloy 800 in aggressive industrial settings. Its resistance to stress-corrosion cracking, pitting, and crevice corrosion makes it exceptionally well-suited for Heating Elements Tubes exposed to corrosive substances like acids and alkalis. The alloy’s robustness in hostile environments ensures uninterrupted operation and reduces maintenance requirements.

4. Excellent Welding and Fabrication Capabilities:

Incoloy 825 offers superior welding and fabrication capabilities compared to Incoloy 800. Its malleability and ease of shaping allow for intricate designs, making it adaptable to complex heating element configurations. This flexibility in manufacturing processes enhances the efficiency and customization possibilities for heating applications.

5. Longevity and Cost-Efficiency:

Incoloy 825’s enhanced corrosion resistance and high-temperature durability result in a longer operational lifespan compared to Incoloy 800. The reduced need for frequent replacements leads to significant cost savings in terms of maintenance and replacement expenditures over the long term, making it a financially prudent choice for industries.

In conclusion, Incoloy 825 Tubes offer superior corrosion resistance, enhanced high-temperature durability, optimal performance in aggressive environments, excellent welding capabilities, and long-term cost-efficiency when compared to Incoloy 800. These advantages position Incoloy 825 as the premier choice for Heating Elements Tubes in various industrial applications, ensuring reliable and efficient heat generation.

Note: For specific inquiries or to explore how Incoloy 825 and Incoloy 800 tube can be tailored to your heating element needs, please feel free to contact our experts. We are dedicated to provide customized solutions that meet the unique requirements of your industry.