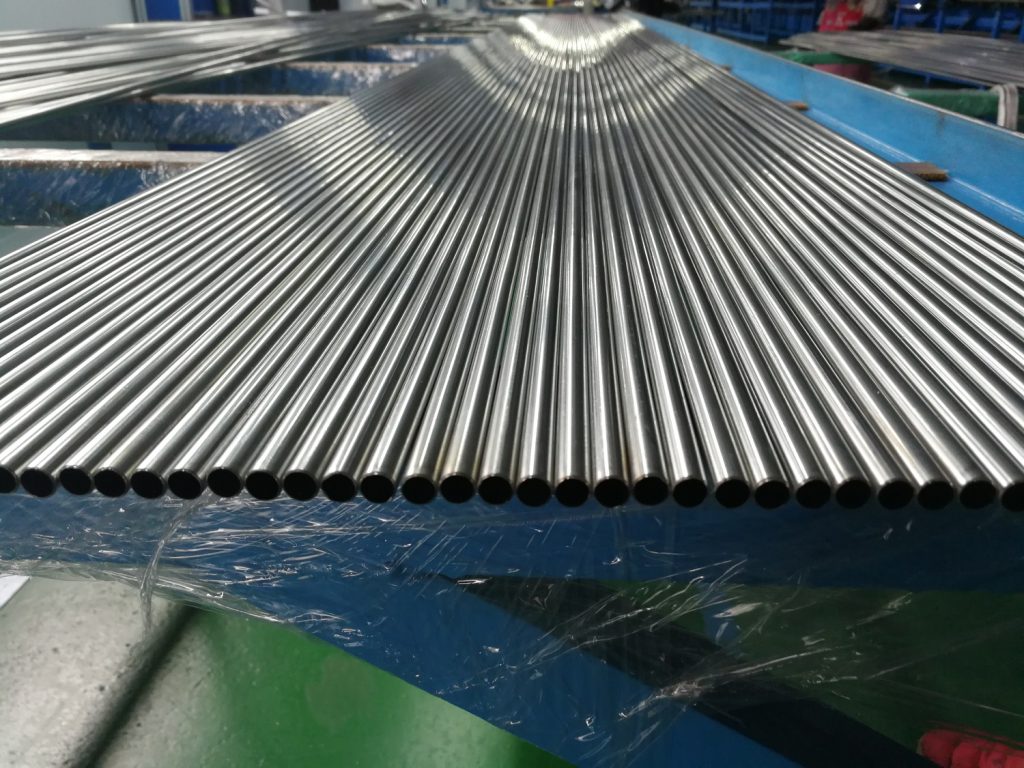

STAINLESS STEEL TUBES & PIPES

WELED, SEAMLESS AND COILED STAINLESS STEEL TUBE

STAINLESS STEEL TUBES & PIPES WE CAN PROVIDE

WHY STAINLESS

Stainless steel is a type of steel alloy that contains a minimum of 10.5% chromium by mass. It is called "stainless" because it exhibits excellent corrosion resistance compared to other types of steel. Stainless steel is a popular choice for various applications due to its numerous advantageous properties. Here are some reasons why stainless steel is often chosen:

Request a QuoteCorrosion Resistance: Stainless steel has excellent corrosion resistance, making it highly resistant to rust, stains, and corrosion in different environments. This makes it suitable for applications where exposure to moisture, chemicals, or harsh conditions is a concern.

Strength and Durability: Stainless steel is a strong and durable material, offering high tensile strength and resistance to wear and tear. It can withstand heavy loads and is often used in structural applications or equipment that requires robustness.

Hygiene and Cleanliness: Stainless steel has a smooth, non-porous surface that is easy to clean and sanitize. It is widely used in industries such as food processing, healthcare, and pharmaceuticals where cleanliness and hygiene are crucial.

Aesthetic Appeal: Stainless steel has a clean, modern appearance that complements various design styles. It is often used in architectural applications, kitchen appliances, decorative elements, and consumer products.

Heat and Fire Resistance: Stainless steel exhibits good resistance to high temperatures and fire. It maintains its strength and structural integrity even at elevated temperatures, making it suitable for applications that involve heat or fire exposure.

Recyclability: Stainless steel is a highly recyclable material. It can be melted down and reused without any loss in quality or performance. This makes stainless steel an environmentally friendly choice.

Wide Range of Grades and Finishes: Stainless steel comes in various grades and finishes, each with specific properties and characteristics. This allows for customization and selection of the appropriate grade for a specific application, such as marine environments (316 stainless steel) or high-temperature applications (such as 310 stainless steel).

Cost-Effective: While stainless steel may have a higher initial cost compared to some other materials, its long-term durability, low maintenance requirements, and extended lifespan can make it a cost-effective choice in the long run.

These are just a few reasons why stainless steel is often chosen for different applications. The specific selection of stainless steel depends on the requirements of the application, such as the desired corrosion resistance, strength, temperature resistance, and aesthetic preferences.

Should you have any interest or specific needs, please do not hesitate to reach out to us. We are here to provide assistance and support.

Should you have any interest or specific needs, please do not hesitate to reach out to us. We are here to provide assistance and support.

FEATURES OF STAINLESS

304: 304 stainless steel is resistant to corrosion and high temperature, and has good processing performance, so it is widely used in industry, furniture decoration industry and food and medical industry.

316L: Compared with conventional chromium-nickel austenitic stainless steel such as 304 stainless steel, 316L has better resistance to general corrosion, pitting corrosion and crevice corrosion. 316L has higher ductility, stress corrosion resistance, compressive strength and high temperature resistance.

309/309S: 309/309S stainless steel can withstand repeated heating below 980 °C, it has high high-temperature strength, oxidation resistance, and carburization resistance.

310/310S: 310/310S stainless steel is an austenitic chromium-nickel stainless steel, which has good oxidation resistance, corrosion resistance, high temperature resistance, and because of the higher percentage of chromium and nickel, it has much better creep strength and can continue to work at high temperatures,

310/310S: 310/310S stainless steel is an austenitic chromium-nickel stainless steel, which has good oxidation resistance, corrosion resistance, high temperature resistance, and because of the higher percentage of chromium and nickel, it has much better creep strength and can continue to work at high temperatures,

it also has good high temperature resistance. Due to the high content of Ni and Cr, it has good oxidation resistance, corrosion resistance, acid and alkali resistance, and high temperature resistance. The high temperature resistant steel pipe is specially used in the manufacture of electric furnace tubes and other occasions.

Duplex 2205: The yield strength of Duplex 2205 stainless steel is more than double that of ordinary austenitic stainless steel. This feature allows designers to reduce weight when designing products, making this alloy more price-competitive than 316, 317L. This alloy is especially suitable for use in the -50°F/+600°F temperature range.

Duplex 2507: Duplex 2507 is a ferritic-austenitic (duplex) stainless steel, which combines the most beneficial properties of many ferritic steels and austenitic steels. Due to the high content of chromium and molybdenum in this steel, it has extremely Good resistance to pitting corrosion, crevice corrosion and uniform corrosion. The dual-phase microstructure ensures that the steel has a high resistance to stress corrosion cracking, and its mechanical strength is also high.

Duplex 2205: The yield strength of Duplex 2205 stainless steel is more than double that of ordinary austenitic stainless steel. This feature allows designers to reduce weight when designing products, making this alloy more price-competitive than 316, 317L. This alloy is especially suitable for use in the -50°F/+600°F temperature range.

Duplex 2507: Duplex 2507 is a ferritic-austenitic (duplex) stainless steel, which combines the most beneficial properties of many ferritic steels and austenitic steels. Due to the high content of chromium and molybdenum in this steel, it has extremely Good resistance to pitting corrosion, crevice corrosion and uniform corrosion. The dual-phase microstructure ensures that the steel has a high resistance to stress corrosion cracking, and its mechanical strength is also high.