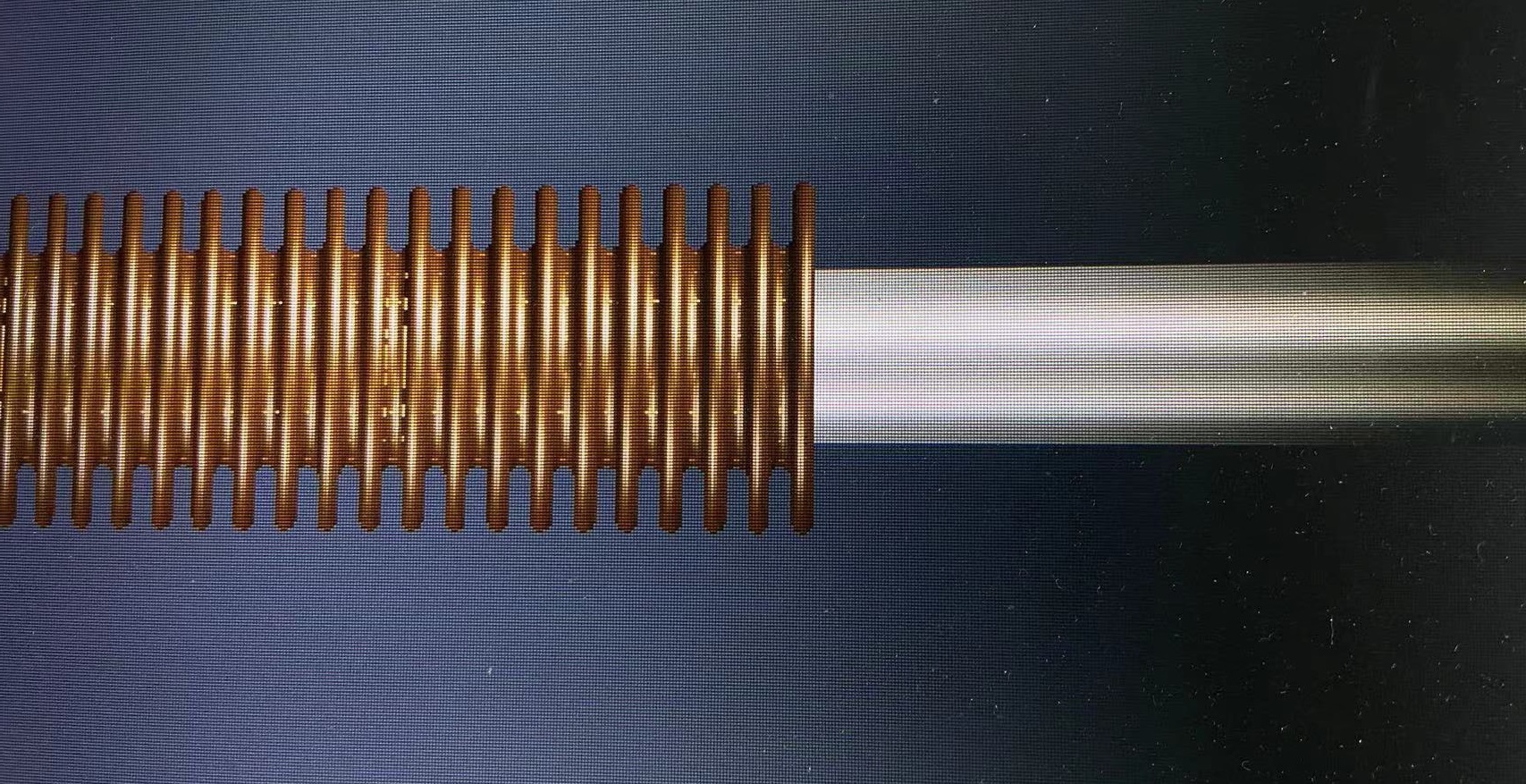

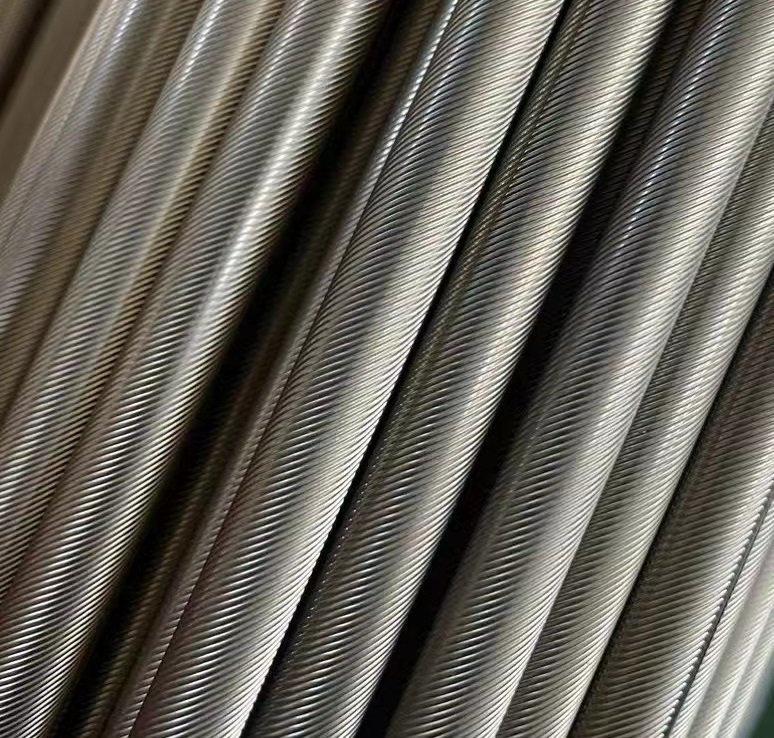

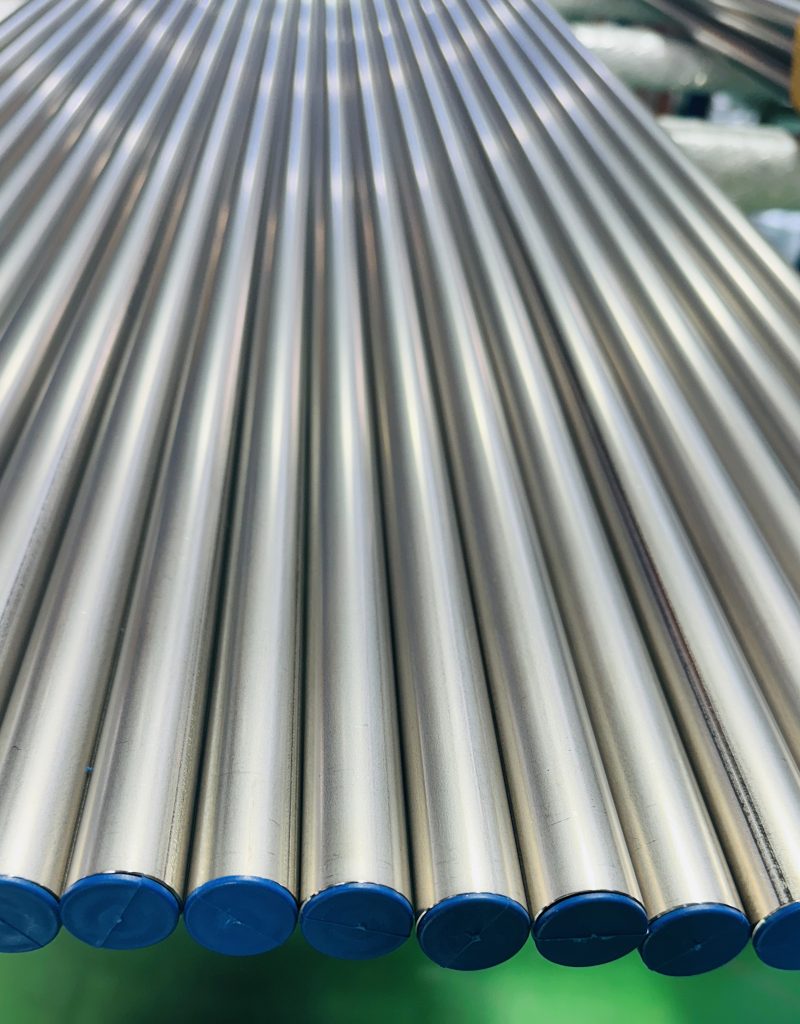

While titanium has a lower thermal conductivity compared to copper or stainless steel, it offers several advantages that make it a valuable material for heat exchangers, particularly in shell-and-tube and plate heat exchangers. These advantages include:

- Exceptional Corrosion Resistance: Titanium is renowned for its exceptional resistance to corrosion, even in aggressive environments like seawater, strong acids, and industrial chemicals. This makes it ideal for applications where the heat exchanger is exposed to harsh fluids or operates in corrosive conditions.

- High Strength and Durability: Titanium exhibits remarkable strength and durability, enabling it to withstand high pressures and temperatures without compromising its integrity. This is crucial for heat exchangers that handle high-pressure fluids or operate in extreme temperature ranges.

- Biocompatibility: Titanium possesses biocompatibility, making it suitable for applications in the medical and pharmaceutical industries, where it can be used in heat exchangers for medical devices or pharmaceutical processes.

- Lightweight: Titanium is significantly lighter than copper or stainless steel, which can be a significant advantage in applications where weight is a critical factor, such as in aerospace or marine applications.

- Low Fouling: Titanium’s natural resistance to surface buildup and fouling reduces the tendency for deposits to adhere to its surface, minimizing the need for frequent cleaning and maintenance.

Despite its lower thermal conductivity, titanium’s superior corrosion resistance, high strength, biocompatibility, lightweight nature, and low fouling properties make it a compelling choice for specific heat exchanger applications. In these cases, the benefits of titanium often outweigh the slight disadvantage in thermal conductivity.

For instance, in seawater applications, titanium heat exchangers excel due to their ability to withstand the corrosive effects of seawater, preventing leaks and extending the lifespan of the equipment. Similarly, in the medical field, titanium’s biocompatibility ensures the safety and purity of fluids used in medical processes.

In summary, while thermal conductivity is an important consideration for heat exchangers, it’s not the sole factor determining material selection. Titanium’s unique combination of corrosion resistance, strength, biocompatibility, lightweight properties, and low fouling makes it a valuable material for specialized heat exchanger applications where these properties are crucial for optimal performance and long-term reliability.