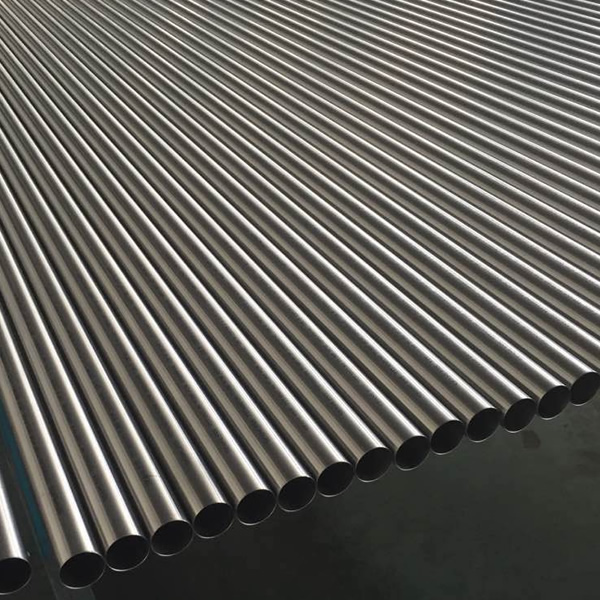

TITANIUM SEAMLESS TUBE

FROM RAW MATERIAL TO FINISHED TUBE PRODUCTS

We offer a dependable solution for your titanium seamless tubes and pipes requirements.

As a professional titanium tube supplier based in China, GAOFA TECH specializes in providing high-quality seamless titanium tubes and alloy tubes. Our product range includes Grade 1, Grade 2, Grade 9, and Grade 5 titanium tubing. We pride ourselves on our innovative approach, which includes enhancing the elongation of 3Al-2.5V tubes and introducing tubing with reduced thickness while maintaining the same outer diameter.

Titanium Seamless Tube Specification:

ASTM B338, ASTM B861

Request a QuoteGrade: Gr1, Gr2, Gr5, Gr7, Gr9, Gr12, Gr13, Gr16, Gr17

Outer Diameter: 6.0mm to 114mm

Wall thickness: 0.4mm to 15.0mm

Length: Less than 18meters

Heat Treatment: Vaccum Furnace Annealing

NDT: Hydrostatic, Pneumatic, E.T. U.T based on standard or customers’ requirements

Introduction

Titanium is an important structural metal developed in the 1950s. Titanium alloys have low density, high specific strength, good corrosion resistance, low thermal conductivity, non-toxic and non-magnetic, weldable, good biocompatibility, surface with strong decorative properties, it is widely used in aviation, aerospace, chemical industry, petroleum, electric power, medical treatment, construction, sporting goods and other fields. Many countries in the world have recognized the importance of titanium alloy materials, researched and developed them one after another, and obtained practical applications.

Request a QuoteIt is hard to find more lighter and corrosion resistant material. Titanium is heat resistant, insensible to temperature changes, pressure resistant and stable in salt, moisture and organic conditions. Titanium alloy is the hardest metal. Titanium tube is required everywhere where it is important be stability to mechanical influences and endurance to aggressive media. Due to high durability, corrosion stability, accumulation of salts and organics on the wall surface titanium alloys keep its qualities and properties.

PROPERTIES OF TITANIUM TUBE

√ High strength-to-weight ratio

√ Excellent corrosion resistance in many media

√ Biocompatibility

√ Low thermal expansion

√ High melting point

√ Smooth surface, no fouling, and greatly reduced fouling coefficient

√ Smooth surface, no fouling, and greatly reduced fouling coefficient

APPLICATIONS OF TITANIUM TUBE

● Heat Exchanger

● Condenser

● MVR(Mechanical Vapor Recompression) Evaporator

● Sea Water Desalinization

● Chemical Equipment

● Heat Pump

● Heating Elements

● Automobile Exhaust system

Gr2 titanium seamless tube is the main product which is widely used in heat exchanger and condenser. Titanium Grade 2 is a "commercially pure" titanium that is commonly used in applications requiring welding due to its strong weldability properties. It is lightweight and highly resistant to corrosion, but its strength is much lower than other titanium alloys. GAOFA TECH adheres to strict quality standards to produce titanium seamless tube to ensure that the final product can fully meet customers’ requirements.

If you want to improve the heat transfer rates, please see our high efficiency heat transfer titanium tube, which is made by titanium welded tube. You can choose this tube if the working pressure is less than 5MPa(725PSI).

Titanium Seamless Tube Chemical Composition (%):

| Grade | N Max | C Max | H Max | Fe Max | O Max | Mo | Ni | Al | V | Pd | Residual Each | Residual Total | Ti |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Gr1 | 0.03 | 0.08 | 0.015 | 0.20 | 0.18 | --- | --- | --- | --- | --- | 0.1 | 0.4 | BAL |

| Gr2 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | --- | --- | --- | --- | --- | 0.1 | 0.4 | BAL |

| Gr5 | 0.05 | 0.08 | 0.015 | 0.40 | 0.2 | --- | --- | 5.5-6.75 | 3.5-4.5 | --- | 0.1 | 0.4 | BAL |

| Gr7 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | --- | --- | --- | --- | 0.12-0.25 | 0.1 | 0.4 | BAL |

| Gr9 | 0.03 | 0.08 | 0.015 | 0.25 | 0.15 | --- | --- | 2.5-3.5 | 2.0-3.0 | --- | 0.1 | 0.4 | BAL |

| Gr12 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | 0.2-0.4 | 0.6-0.9 | --- | --- | --- | 0.1 | 0.4 | BAL |

| Gr16 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | --- | --- | --- | --- | 0.04-0.08 | 0.1 | 0.4 | BAL |

Titanium Seamless Tube Mechanical Properties

| Grade | TENSILE STRENGTH MPa | YIELD STRENGTH Rp0.2, MPa | ELONGATION A50mm, % |

|---|---|---|---|

| Gr1 | ≧240 | 138 - 310 | ≧24 |

| Gr2 | ≧345 | 275 - 450 | ≧20 |

| Gr5 | ≧895 | ≧828 | ≧10 |

| Gr7 | ≧345 | 275 - 450 | ≧20 |

| Gr9-Annealed | ≧620 | ≧483 | ≧15 |

| Gr9- CWSR | ≧860 | ≧725 | ≧10 |

| Gr12 | ≧483 | ≧345 | ≧18 |

| Gr16 | ≧345 | 275 - 450 | ≧20 |

Standards:

Tubes & pipes: ASTM B338, ASTM B861

Titanium Density:

0.163 lb/in3 (4.51g/cm3)

Titanium Seamless Tube Advantages

(Comparing to Titanium Welded Tube):

√ Small quantity order acceptable.

√ Higher pressure working condition.

√ Better controlling of Mechanical Properties.

√ A lot more heavier wall thickness can be made comparing to titanium welded tube.

Titanium seamless tubes possess identical features and applications as welded tubes. However, for applications with lower working pressure requirements, it is advisable to consider titanium welded tubes as a suitable alternative.