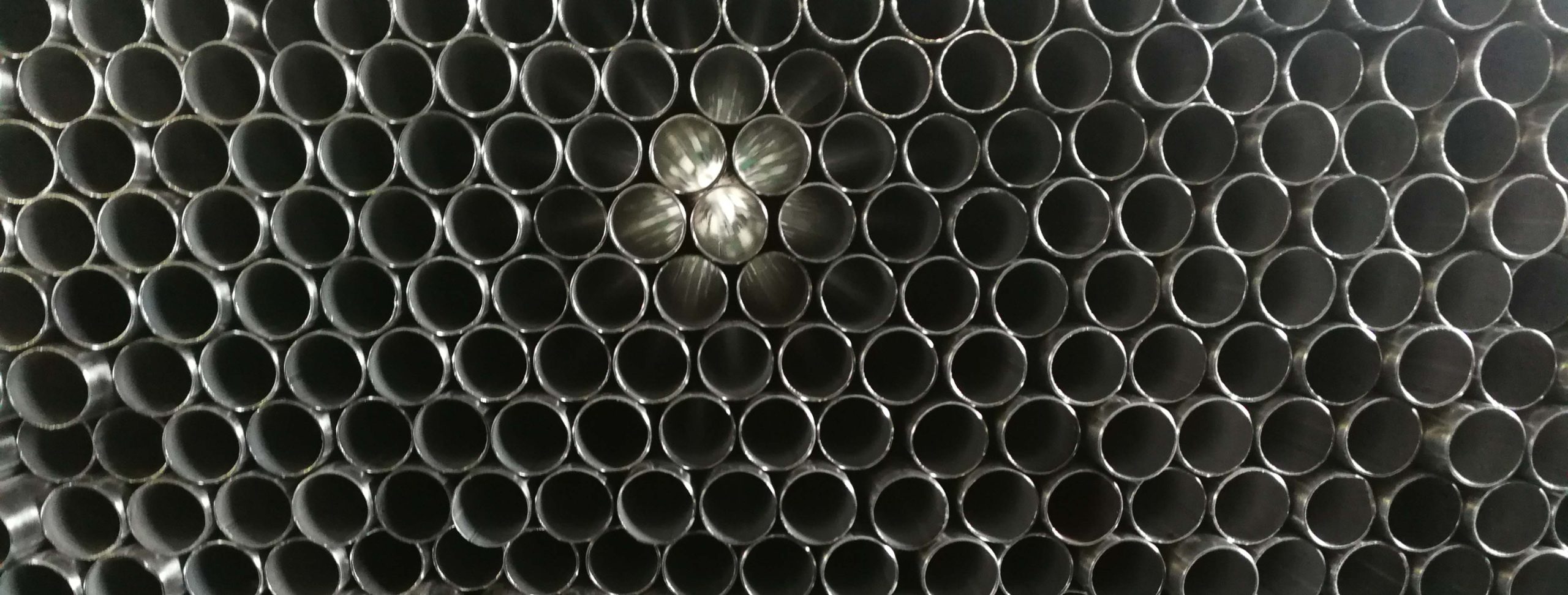

Introduction to Titanium:

Titanium, a robust and lightweight metal, has found remarkable applications in various industries. Its unique combination of strength, corrosion resistance, and low density makes it an ideal choice for demanding environments.

Titanium Tubes in Heating Elements: Characteristics and Advantages:

- Exceptional Corrosion Resistance:

- Benefit: Titanium’s innate resistance to corrosion ensures the longevity of heating elements, particularly in harsh or corrosive conditions.

- High Temperature Strength:

- Benefit: Titanium tubes maintain structural integrity at elevated temperatures, contributing to the efficiency of heating processes.

- Low Density and Lightweight:

- Benefit: The low density of titanium makes heating elements lightweight, simplifying installation and handling without compromising strength.

- Biocompatibility:

- Benefit: Titanium is biocompatible, making it suitable for heating elements used in applications where contact with sensitive materials is crucial, such as in medical devices.

- Efficient Heat Transfer:

- Benefit: Titanium tubes facilitate efficient heat transfer, enhancing the overall performance and energy efficiency of heating elements.

- Oxide Film Formation:

- Benefit: Titanium naturally forms a protective oxide film, preventing scale buildup on the tube surface and ensuring consistent performance over time.

- Durability in Aggressive Environments:

- Benefit: Titanium’s resilience to aggressive substances makes it a preferred choice for heating elements in applications involving corrosive or chemically aggressive environments.

Applications in Heating Elements:

- Industrial Heating Systems:

- Titanium tubes are integral components in industrial heating systems, ensuring reliability in demanding temperature conditions.

- Medical Devices:

- Biocompatibility makes titanium tubes suitable for heating elements in medical devices, where safety and reliability are paramount.

- Chemical Processing:

- In chemical processing industries, titanium tubes contribute to the efficiency and longevity of heating elements used in corrosive environments.

- Aerospace Industry:

- The lightweight yet robust nature of titanium tubes makes them valuable in heating elements for aerospace applications, contributing to fuel efficiency.

In conclusion, the integration of titanium tubes in heating elements represents a synergy of material excellence and engineering innovation, providing unparalleled performance and durability in a variety of applications.

Note: For specific inquiries or to explore how titanium tubes can be tailored to your industry equipment’s needs, please feel free to contact our experts. We are dedicated to provide customized solutions that meet the unique requirements of your industry.